The Ditchburn Mk2R Music Maker 30 Part 2

Restorations.

PART 2: Karl Dawson’s MK2R Music Maker 30 Serial Number 2594

This

Machine

first

started

its

life

as

a

MK2

16

selection

78

RPM

machine,

at

some

point

after

1955

it

was

returned

to

the

Dock

Road

factory

in

Lytham

and

converted

to

a

30

play

45

RPM

machine,

the

original

mechanism

was

built

in

the

UK

under

license

from

the

USA

company

Wurlitzer,

but

the

30

Play

conversion

kit

was

designed

totally

by

Ditchburn,

as

far

as

we

know

Wurlitzer never made a 30 play 45 rpm mechanism.

As

mentioned

in

the

last

section

of

part

1,

I

decided

that

a

strip

down

was

required

as

a

lot

of

the

parts

were

coated

in

old

solidified grease and needed to be cleaned and lubricated.

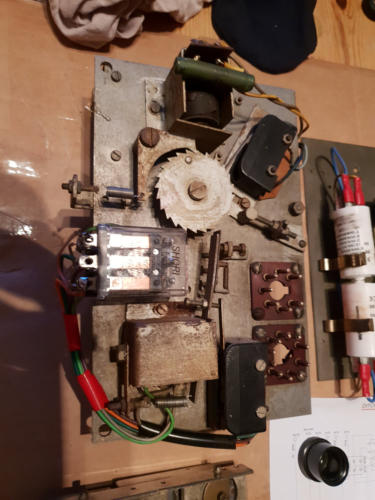

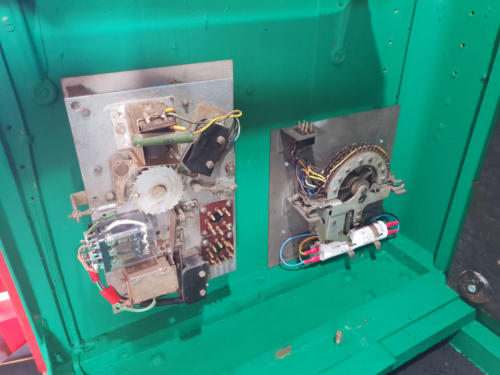

First

i

started

with

the

credit

units

The

first

is

the

original

credit

unit

that

was

modified

a

credit

removal

coil

and

relays

this

unit

adds

1

credit

for

every

6d

inserted

and

every

time

a

record

is

selected

a

credit

is

removed.

this

unit

also

was

modified

with

relays to switch the motor run and the amplifier mute circuits. also additional capacitors had been fitted to de-bounce the coils.

All

the

capacitors

needed

replacing

as

they

were

old

type

electrolyte

caps

and

were

showing

signs

of

aging

and

failure,

also

the

relays

were

replaced

as

the

contacts

were

in

bad

in

a

bad

state,

you

can

see

that

the

back

relay

that

mutes

the

amp

between

plays

has

a

burnt

contact,

that

is

because

the

original

relays

were

not

rated

at

300vdc

and

the

Valve

HT

took

its

toll

over time.

Add and Deduct a Credit Unit

Front

( before restoration )

Back

( before restoration )

Photo Ref: DB301 Courtesy of Karl Dawson.

Photo Ref: DB303 Courtesy of Karl Dawson.

Front

( after restoration )

Back

( after restoration )

Photo Ref: DB302 Courtesy of Karl Dawson.

Photo Ref: DB304 Courtesy of Karl Dawson.

All

the

mechanical

parts

were

removed

and

cleaned,

the

star

wheel

was

lubricated

using

a

fine

Graphite

powder

do

not

use

oil

as

this

will

cause

dust

to

stick

to

the

shaft

and

will

prevent

the

wheel

free

running.

the

caps

were

replaced,

and

the

relays

were replaced with higher rated and sealed units.

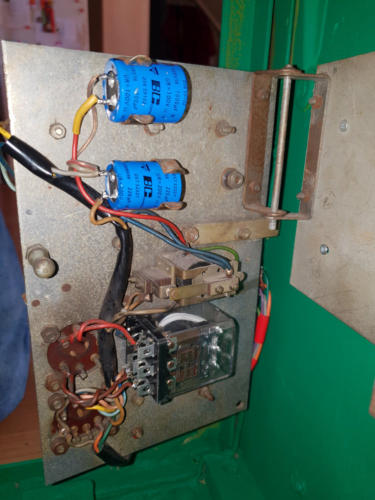

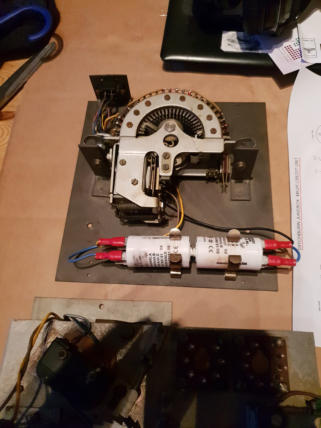

3 plays for 1 Shilling Unit

This

Unit

provides

3

pulses

to

the

credit

unit

above

on

insertion

of

a

shilling,

This

unit

took

a

bit

of

work

to

restore

it

uses

a

GPO

uni-selector

that

has

a

wiper

contact

that

moves

1

position

for

every

pulse

on

the

step

coil

and

on

insertion

of

a

shilling

it

will

step

across

the

25

positions

from

start

to

finish.

some

of

the

contacts

had

dirt

and

corrosion

on

them

so

it

took

a

bit

of

work

to

clean

them,

the

unit

uses

two

capacitors,

both

these

needed

replacing,

the

first

one

acts

as

storage

for

the

coil

and

the

second

capacitor

prevents

the

credit

coil

on

the

unit

above

from

dropping

out

as

it

steps

between

the

25

individual

contacts, these units fit onto the side of the cabinet.

Photo Ref: DB305 Courtesy of Karl Dawson.

Photo Ref: DB306 Courtesy of Karl Dawson.

( before restoration )

( after restoration )

Photo Ref: DB307 Courtesy of Karl Dawson.

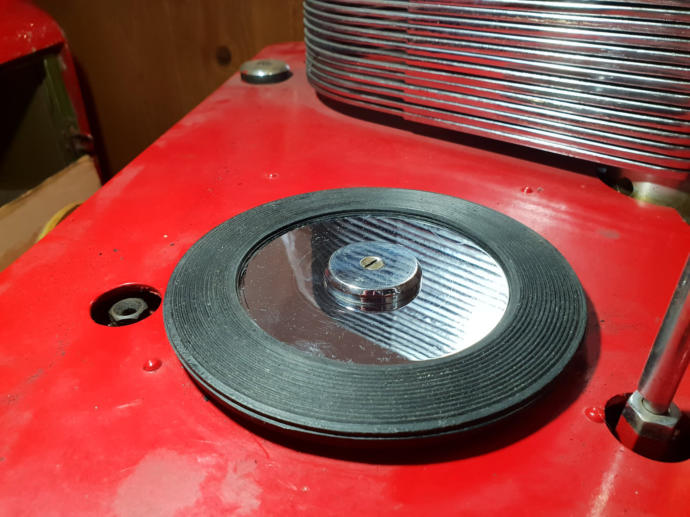

The Turntable

The

Rubber

turntable

mat

had

over

time

become

hard

and

brittle

and

lost

its

grippy

surface,

I

thought

it

was

going

to

be

difficult

to

find

a

replacement,

but

i

noticed

that

the

Ami

R84

mat

was

very

similar

and

thought

it

may

need

some

trimming

to

fit

but

when

it

arrived

i

found

it

was

identical

in

size

to

the

original,

but

the

bottom

had

fixing

protrusions,

so

it

was

a

simple

process

of

slicing

these

off

flush

with

the

surface

and

gluing

the

mat

to

the

turntable,

i

cleaned

the

platter

and

hub

chrome

with

metal polish and it was as good as new.

Photo Ref: DB308 Courtesy of Karl Dawson.

Photo Ref: DB309 Courtesy of Karl Dawson.

Photo Ref: DB310 Courtesy of Karl Dawson.

Photo Ref: DB311 Courtesy of Karl Dawson.

Photo Ref: DB312 Courtesy of Karl Dawson.

The Record Stack

The

record

stack

had

become

stiff

over

time

due

to

the

oil

and

grease

solidifying,

so

i

decided

to

strip

down

the

stack

and

clean

and

polish

each

tray,

the

grease

was

difficult

to

remove

but

underneath

the

chrome

was

still

top

quality

so

only

metal

polish

was

used

to

bring

back

the

shine

on

each

stack,

on

reassembly

i

used

a

few

drops

of

3in1

oil

between

each

washer

and tray and also in the spring linkage. the trays were exceptionally free moving after this.

Photo Ref: DB313 Courtesy of Karl Dawson.

Photo Ref: DB314 Courtesy of Karl Dawson.

Photo Ref: DB318 Courtesy of Karl Dawson.

Photo Ref: DB319 Courtesy of Karl Dawson.

Photo Ref: DB320 Courtesy of Karl Dawson.

Photo Ref: DB321 Courtesy of Karl Dawson.

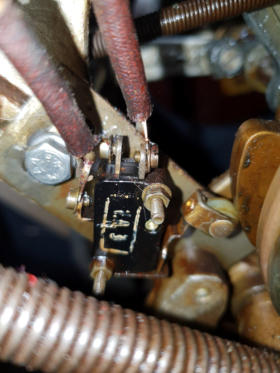

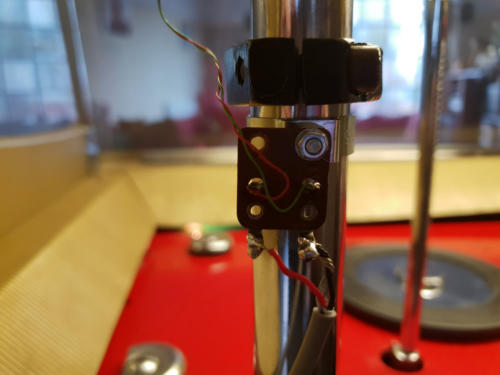

Switches

The

end

of

record

trip

switch

and

the

cam

cycle

start

switch

was

in

bad

condition,

so

replaced

the

trip

switch

with

a

new

sensitive micro-switch, these switches are used in coin slots so take very little tracking pressure to activate the contacts.

and the cycle start switch was replaced with a heavy duty micro switch

Old

New

Photo Ref: DB322 Courtesy of Karl Dawson.

Photo Ref: DB323 Courtesy of Karl Dawson.

Old

New

Photo Ref: DB325 Courtesy of Karl Dawson.

Photo Ref: DB326 Courtesy of Karl Dawson.

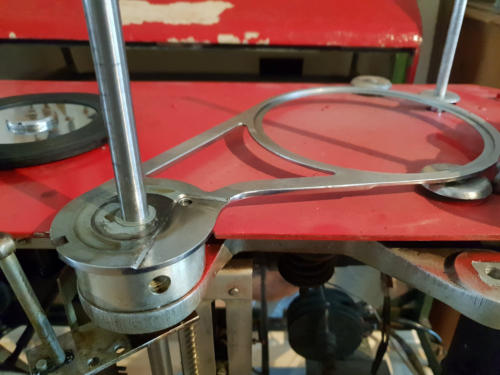

The Tonearm

The

Tonearm

trip

assembly

was

stripped

down

the

solidified

grease

was

removed

and

the

bearings

made

free,

and

some

light

oil

was

applied,

the

supports

and

mount

were

cleaned

and

re-painted

black.

a

tag

strip

was

added

to

the

support

using

a

spring clip to allow for easy servicing. and the unit reassembled and tested with the start and trip positions on the record.

Photo Ref: DB327 Courtesy of Karl Dawson.

Photo Ref: DB340 Courtesy of Karl Dawson.

Photo Ref: DB341 Courtesy of Karl Dawson.

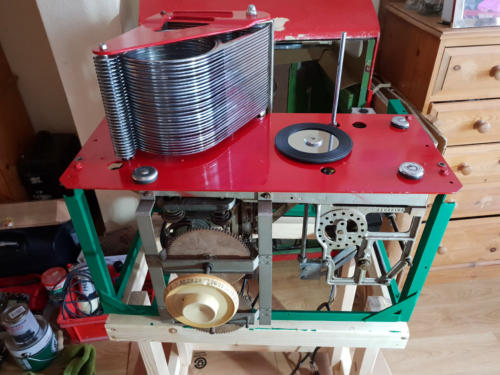

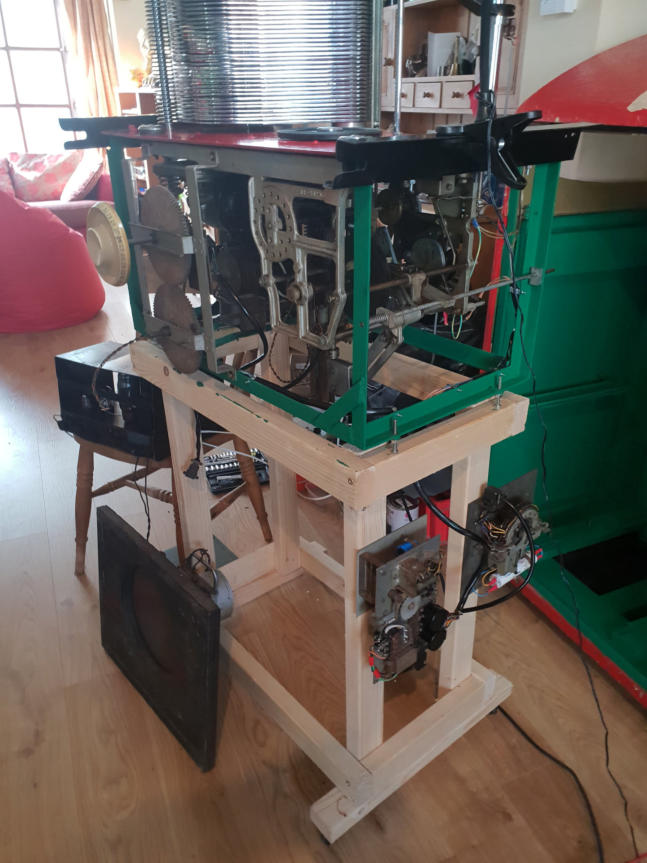

The Final Test

Before

putting

the

Mech

back

into

the

cabinet,

i

decided

to

first

test

the

mech

on

the

trolley,

connecting

everything

together.

it

also allowed me to set up the record start and end trip positions easily.

Photo Ref: DB333 Courtesy of Karl Dawson.

The Videos

Thank you for watching, there’s another restoration starting soon.